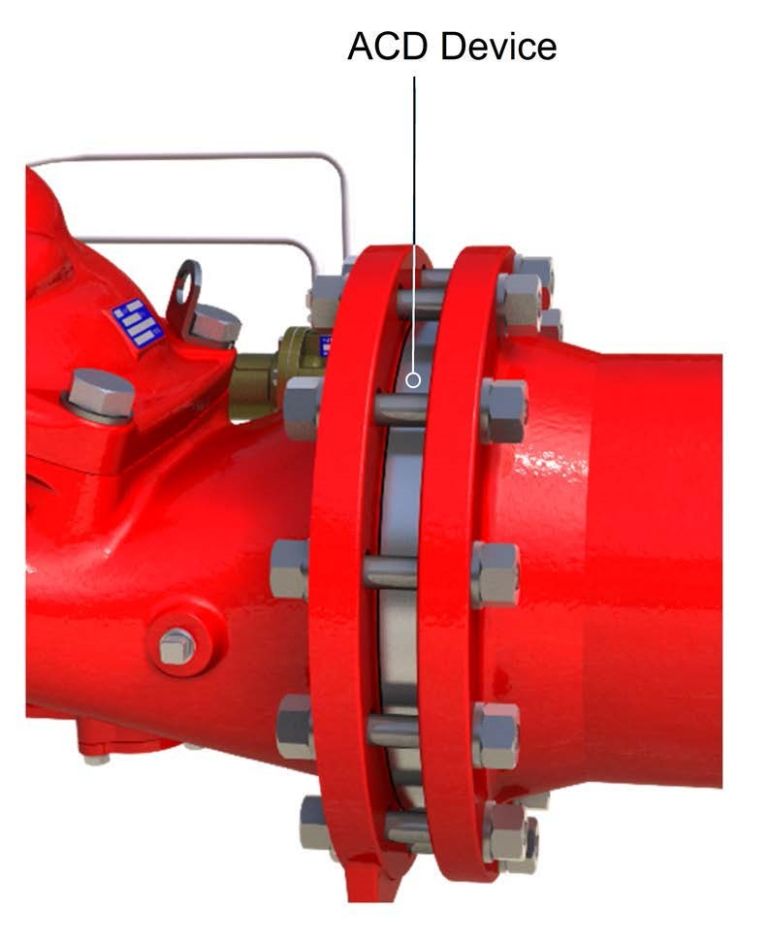

ACD – Anti-Cavitation Diffuser Device

The Anti Cavitation Diffuser (ACD) is a device designed to prevent cavitation damage at source, also reducing noise levels and vibration.

This device replaces traditional anti-cavitation trims, and will prevent flashing and cavitation pitting of valves and piping operating at high pressure differentials.

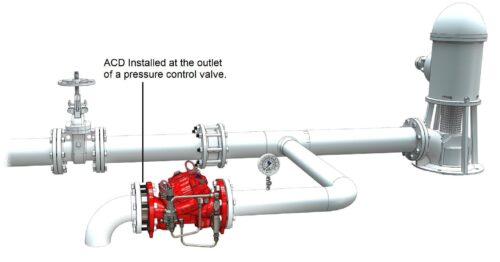

The ACD should be installed at the outlet, downstream of Pressure control or Pressure Relief valves thereby controlling the pipe velocity profile and the pressure characteristic across the control valve seat.

The ACD will eliminate and silence cavitation, minimizing erosion damage and will significantly extend operating life and minimize downtime in applications working in severe service conditions.

Product Features & Benefits

- Prevents cavitation / erosion damage of valves – extending operating life in severe conditions.

- Replaces traditional anti-cavitation trims – At lower cost.

- Corrosion Resistant Material – Suitable for Seawater / Corrosive fluids.

- Straight through free flow – Reducing vibration and noise level.

- No moving parts – Ultimate reliability, no danger of clogging or wear.

- Installation at the same valve connection size – meets the NFPA 20 fire pump data.

- Wafer flange connection – Easy field installation

Typical Product Applications

- High differential pressure relief valves

- Severe service pressure control valves

- Noise and vibration reduction

- Pressure Control Valves (PCV)

- Pump recirculation

Installation

The BERMAD Anti-Cavitation Diffuser (ACD) shall be installed in any orientation, vertical or horizontal or otherwise it shall be mounted between two flanges at the outlet of the BERMAD pressure relief/sustaining valve. Make sure to install a proper gasket on each side of the ADC facing. The upstream and the downstream piping shall be well supported to eliminate vibrations.